[NOTE: Please see our update regarding this printer: Finding the best dirt-cheap, field-tough 3D printer for science and conservation work: six months later.]

Monoprice is an interesting organization. They’re a rebadging company that seeks out unbranded or off-brand products, makes a few tweaks, and then sells them to secondary markets under their own brand. They made their mark in the early 2000s selling good, cheap cables and have expanded from there. You can find headphones, cookware, cables, computer accessories, and, of course, 3D printers, under the Monoprice label. But that doesn’t mean their products are cheap knockoffs. Monoprice has a reputation for finding quality equipment.

The Monoprice Mini Delta is a rebadged Malyan M300. From the specs, it doesn’t look like Monoprice changed anything but the logo, and that’s a good thing. Malyan printers have a great reputation.

This is a delta printer, which means rather than having independent X, Y, and Z-axes, three identical stepper motor arrays work in tandem to control the position of the extruder while the bed itself remains stationary. It uses a Bowden-style extruder that keeps the weight on the printhead down. It has an aluminum frame with steel structural elements. The relatively small circular print area is 110 mm diameter by 120 mm height. Controls are integrated into the printer and it allegedly has WiFi capability through an app.

The Monoprice Mini Delta is available on Amazon for $159.99.

We’re going to make this little printer suffer.

For an explanation of our testing protocols, please see: We’re gonna beat the heck out of these machines: The search for the best dirt-cheap 3D printer for fieldwork.

The Burn In.

Unlike many sub-$200 printers, the Mini Delta comes pre-assembled and true to its promise is ready to go out of the box. I start all new printer tests using their demo print g-code if provided (and usually without looking up what the print is, for an additional surprise) and whatever filament the printer ships with. The Delta did not come with any filament, so I loaded it with an ancient role of red Hatchbox filament.

From out of box to running the first print was barely 3 minutes. The auto-bed leveler worked as expected and the Lucky Cat that emerged from the bowels of the included mini-SD card looked great.

Before the formal review, I spent some time printing a few random objects to get a feel for how the printer behaves. Already, I could tell that bed adhesion was going to be an issue. The included bed pad is plenty grippy but the heating element is wimpy and small. Since the heating element doesn’t cover the full bed, you’re guaranteed to get inconsistent thermals across the print area, leading to warping on bigger prints.

Burn-in Score: A

The Benchmark Test.

This is a nice, clean Benchy. It’s not the best you can get on something like an Ultimaker or Prusa I3, but it contains no glaring problems. There’s some stringing across the doorways, a little drooping on the bridges, and it struggled to connect the arches. But the bottom text is clearly visible, it did great on the overhangs, the flat surfaces are good and smooth, and you can even read the little plaque on the stern. A benchmark like this, while not perfect, suggests that there are no major issues with the printer.

Benchmark Score: B

The Replication Test.

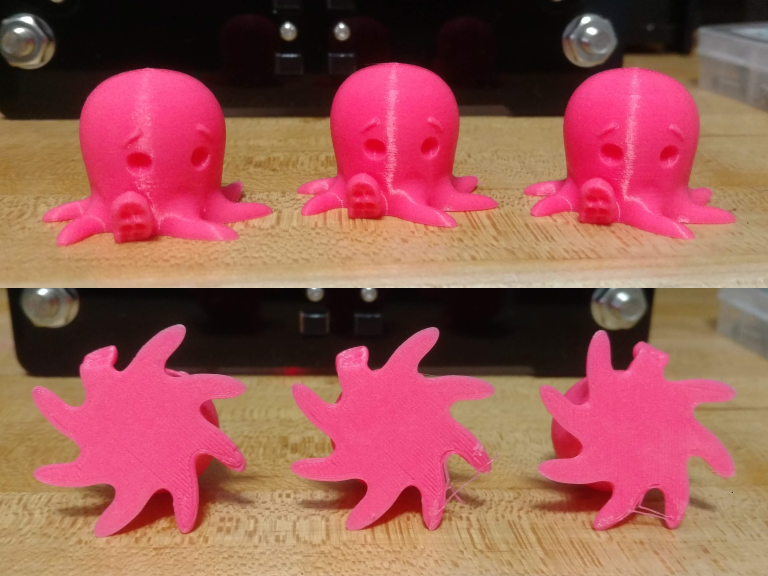

Cute Octo Says Hello is a print you’ll find in almost any Maker Space, and for good reason. This small trinket is great for testing out your printer’s reliability. The Mini Delta churned out 3 of these in rapid succession.

The verticals looked great, with no errors, missed lines, strings, or other defects. But, as predicted, bed adhesion was a problem, with a few early failed prints (failed prints are accounted for collectively in the trash test, rather than for each individual challenge). Even with the good prints, you can see some stinging on the first layer and warping as parts of the arms bow up from inconsistent heating. Annoyingly, the zone of failure was not consistent across prints.

This is a printer that needs to be babysat for the first few layers to ensure the print sticks but once it’s going, it’s good to go.

Replication Score: B

The Functional Parts Test.

The nut and bolt printed cleanly with no obvious defect, fit together, spun freely, and formed a strong bond when loaded.

Functional Part Score: A

The Complex System Test.

This one feels almost unfair. During the course of this test, I realized that our 3D-printable Niskin bottles needed a serious overhaul. So the whole system went back for a redesign and got a linear trigger and gear-driven actuator, as well as a control box. And I ditched the end catches in favor of a cleaner design. So not only was this printer able to print the entire system, but it was used to rapid prototype, iterate, and improve the system.

And it printed a working Niskin3D in both original and new flavors.

That’s all you can ask for.

Complex System Score: A

The Precision Instrument Test.

Is it fair to push a $150 printer down to a resolution that even some professional grade printers can’t handle? Maybe not, but that’s what we’re doing. This vernier scale, designed to be slotted into an open-source octant, is barely longer than a centimeter and needs precise markings. The Printrbot can do it.

The Monoprice Mini Delta cannot. Though, if you absolutely had to use this machine, the vernier scale is not completely unusable.

Precision score: D

The Educator’s Test.

The Isopod looked great! You can clearly see mouth parts and the spines on the telson are clean and sharp. Unsurprisingly, there was a tiny bit of warping due to bed adhesion issues, but nothing dramatic.

Educator’s Score: A

The Tear-down.

I tore this printer down to its bones, exposing every belt, motor, and control module to assess just how tough it would be, and the results are mixed. It’s a very well designed machine that suffers from rushed assembly. Wire management is non-existent, with the main cooling fan blocked by a rat’s nest of cables. About half the screws were stripped. And the heating element was woefully under-powered for the already tiny build area. The motors are wimpy, but the design of the extruder and hot end means you don’t need much power from them. The frame brackets use friction to capture the panels, which could easily shake loose during rough travel.

There’s a lot of good in this system. The axis end stops are optical, rather than contact switches, so they won’t break or wear out. The belt assembly is easy to tighten. The bed leveler is brilliantly minimalist. And the buttons feel solid, clicky, and durable.

The biggest plus is the aluminum frame, which is light and tough. When assembled, there’s almost no flex in it with minimal vibrations. It looks and feels like it could take a beating. The design of the enclosure and the stoutness of the frame leaves me with little doubt that this printer would hold up to a field season. As a small plus, the box it was shipped in comes with good, form-fitting Styrofoam that will protect the print head and I’d just keep that for packing and transport.

The one feature that scares me is the cheap power supply, which sparked several times during these trials. If I put this printer into regular use, that power supply is going straight into the e-waste bin.

Tear-down Score: B

The Trash Test.

While there were no epic print failures during testing, this printer did have some early production fails due to bed adhesion which produced a decent amount of waste, some of which may be offset by the fact that the stable build platform meant that I didn’t need to use so much support structure for big, overhanging pieces.

Total mass of waste filament: 8.35g

Reviewer’s Discretion.

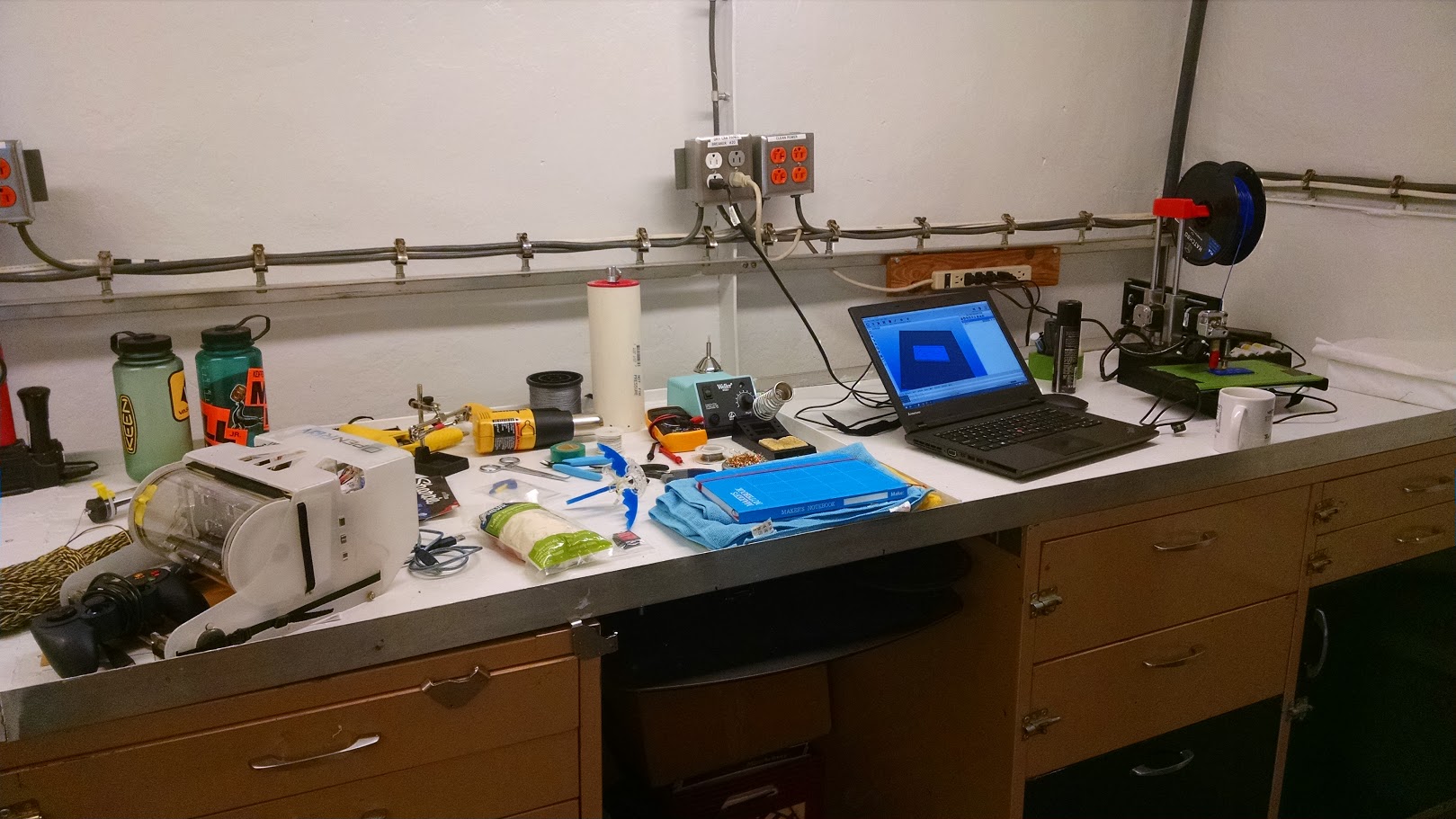

I wanted to hate the Monoprice Mini Delta. Monoprice, more than any other company, is responsible for the downfall of my beloved Printrbot. An American-made 3D-printer at the $599 price point just could not compete with the influx of low-cost Chinese printers. But this is a really good printer. Once you get a handle on the bed adhesion issues, it’s reliable, has good resolution, and produces nice, clean prints. I also like how small the footprint is. With a small modification to mount the filament spool on top of the printer, it barely takes up any desk space.

What I really like about delta printers is that since the three stepper assemblies are identical, you don’t need to carry extra parts for each axis, making repairs easier. I personally prefer direct-drive extruders, which I feel give better accuracy and control over the filament, but with steppers this puny, a motor on top of the hot end would grind this printer to a halt.

The heated bed is pathetic and the power supply actually scares me. This printer is also fairly loud, clocking in at a healthy 67.5 decibels.

With as many pros as cons, I award no extra credit.

Final Assessment.

Would I take this into the field? Yes. After a few modifications. Without question, it needs a different power supply. I’d also upgrade the heated bed and add a borosilicate glass build surface to get cleaner prints with better adhesion, but there are no major mechanical changes that need to be made. If you really wanted to, you could upgrade the hot end to an E3D, but I don’t feel that’s really necessary. Since quality of assembly is so inconsistent, I’d recommend a complete tear-down before putting this into heavy use to tighten up loose screws, re-route the wires away from the cooling fan, and add some locktite to the bracket connectors.

There’s a fantastic community-lead Wiki that guides users through every aspect of this little printer.

Final Score: B-

The rankings so far

- Creality Ender-3 (with upgrades): A

- Monoprice Select Mini: B+

- Monoprice Mini Delta: B-

- Creality Ender-3 (unmodified): B-

- Anet A6: D+

- iNSTONE Desktop DIY: No

Depending on how successful this project is, I may expand to include printers in the $200 to $400 price range. If you want to help make that happen, you can either use the Amazon Affiliate links in the post to buy printers, consumables, anything else or you can sign up for my Patreon and help support Southern Fried Science.