3D Printing. No new technology in the last decade has been heralded with as much hope and hyperbole as the promise of desktop replicators fabricating whatever object you need at the push of a button. 3D printing has made huge steps forward, with more sophisticated machines at lower prices, new materials that vastly expand the printer’s capabilities, and the breathless optimism that foresees a printer in every home, as mundane and easy to operate as a conventional printer*.

And yet, for all the hype, most personal 3D printers are pressed into service fabricating plastic tschotskes — low quality, low function items of little to no utility. While the raw potential of 3D printing continues to expand, the promise of personal printers seems mired in the sandbox: an expensive toy for grownups. A toy that produces heaps of plastic detritus that will eventually find it’s way into the environment.

I posit here that, while it is true the the vast majority of people currently have no practical need for a 3D printer, under the right circumstances, a personal 3D printer can be an incredibly useful tool in the modern home.

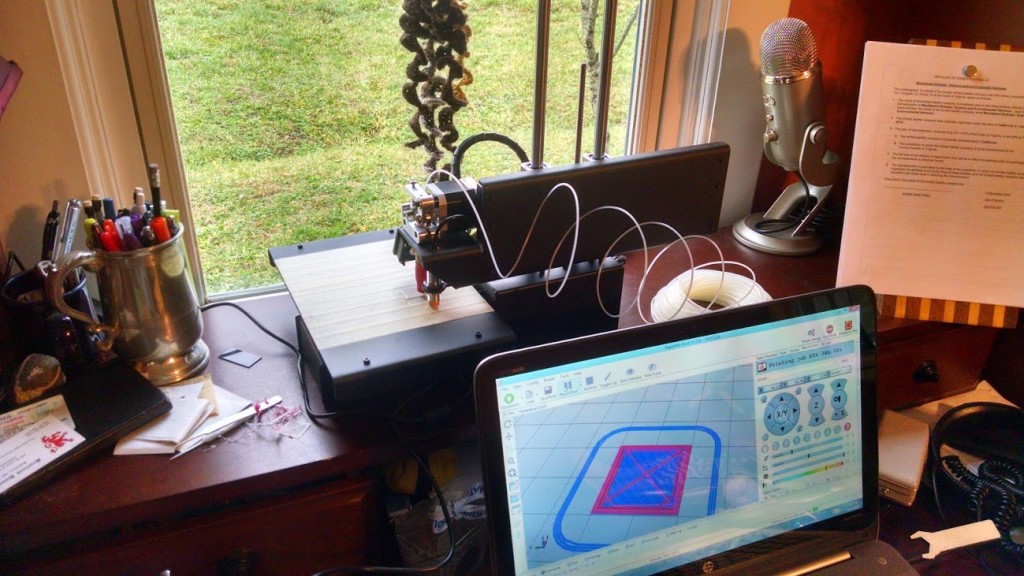

A little over a year ago, we bought a personal 3D printer. It’s a Printrbot Simple Metal, a tough, no nonsense machine that works as well in my home office as it does at sea. Its footprint is small, and it can handle object up to 150 mm by 150 mm by 150 mm. Not huge, but big enough to be useful. And yes, this printer has primarily been used to fabricate parts for Oceanography for Everyone and other scientific endeavors. You can read more about that here: A 3D-printable, drone and ROV-mountable, water sampler and Oceanography for Everyone: Empowering researchers, educators, and citizen scientists through open-source hardware. I’m not talking about the scientific utility of the printer, but rather, how it fits into our homestead.

3D printing is a skill. The current generation of printers are not plug-and-play. You will need to learn the software, learn how to maintain and service them, and learn how to prepare your machine for printing and troubleshoot failed prints. To get the most out of a 3D printer, you’ll need to learn the basics of 3D design and prototyping. This can include 3D scanning and computer aided design. Fortunately, there is a host of free software at your disposal.

You still need to think about plastic. 3D printers use fused plastic filament to print objects. There is plastic waste involved in 3D printing. PLA and ABS, the most common printer plastics, are recyclable. You could also invest in your own filament extruder, and recycle your own 3D prints.

There have been a number of articles over the years discussing how a home 3D printer can pay for itself. I find these to be wildly optimistic. Just considering home use, a year of 3D printing has not come close to covering the cost of the printer, but that doesn’t mean it doesn’t have value. The printer has allowed me to make custom objects quickly and cheaply, and can fabricate replacement parts without the hassle and expense (both financially and environmentally) of shipping.

A Tour of the 3D Printed Home

The Kitchen: You don’t want to dine on PLA or ABS parts, but your can use it for storage. We’ve fabricated coffee scoops, storage containers, bag clips, and other small objects (like an extra large scoop for rabbit food and a baggie holder for the dog). There are some really cool kitchen Things available for download.

The Bathroom: Small hooks, soap dishes, toilet paper rolls, and toothbrush stands can all be readily found on Youmagine or Thingiverse. I wouldn’t recommend printing a showerhead, as the hot water will eventually melt the part.

The Home Office: I’ve made headphone stands, earbud holders, pencil/notebook holders, and other simple office supplies as needed and on demand. I also have these great name plaques in my other office that add a bit more flair to my room assignment.

The Living Room: You know, those small plastic tchotchkes do make pretty useful toys when kids come around (though the printing process itself tends to be infinitely more fascinating to them). Small keychains and keyring holders to help keep all the different keys organized are also handy. There are also plenty of good looking picture frames available to help decorate.

Outside: Hose couplers are really useful in an pinch, as are pots and watering cans if you have the volume. Combined with other DIY projects, you can build entire autonomous garden set ups with a 3D printer and some basic electronics.

Some big weird things: We designed an extension for our chicken brooder to keep the new chicks from flying out. It has already proven itself invaluable. In the workshop, printing custom jigs with 100 micron tolerances is fantastic for furniture and farm crafting. Once you start looking at workshop needs, the possibilities for 3D printing really shines. For DIY enthusiasts, the potential to print parts to replace broken appliances is huge. One day soon, manufacturers will begin offering shapefiles for download rather than mailing tiny parts for repairs. McMaster Carr already offers downloads of most of its hardware, if you ever need a not-quite-loadbearing screw in a pinch.

So does home 3D printing live up to the hype? Not, really, no. We’re a long way from Star Trek replicators. But it absolutely can be useful and reasonably cost efficient (especially as the price of printers keeps dropping). If you have the time and inclination to tinker and create your own custom parts, 3D printing can open up a world of possibilities for the home.

Here’s where the return-on-investment of personal printers really shines: If you have a bit of design skills, and want to create custom home decorations, and the look of 3D printed parts fits your design aesthetic, you can create some truly beautiful functional objects for a fraction of the traditional cost.

With a year of home 3D printing behind me, as well as heap of other prototyping projects, I’ve identified several key areas where, with a little bit of effort from the broader 3D printing community, a home 3D printer could really provide value to a family.

Toddler shoes. Imagine if, instead of buying baby and toddler shoes every few months (at $10 or $20 a pop), you could print durable, correctly sized kids’ shoes out of flexible filament like NinjaFlex for a few cents a pair?

Appliance parts that commonly fail. Most appliances have one or two parts that break predictably. A database of those parts, available for download, could save people from the headache of waiting days or weeks for a replacement part.

Precision measurement jigs and guides. Even the cheapest 3D printers print at 100 micron resolution. Being able to print precision measurement on demand (think spacers for a new tiling project, shims for cabinets, measuring cups, even rulers) can cheaply fulfill those needs.

Toys. You can 3D print just about anything, and many of those Things already are toys.

3D printing is getting better every year. Good printers now go for as little as $300. Mattel is coming out with it’s own printer, for kids. Now that the hype of the 3D printing revolution is finally beginning to die down, we can begin to realize the full, practical potential of home 3D printing.

Welcome to the future.

If you like articles like this and want to support Southern Fried Science or any of our other weird and wonderful projects, head on over to my Patreon page and consider subscribing. Even a few dollars a month goes a long way. You can find my 3D printer designs on YouMagine.

*For what it’s worth, I have an HP wireless printer/scanner. It is significantly less reliable and more difficult to operate than my 3D printer (and costs more in consumables).