Last week, we launched a novel little experiment in crowdfunding marine science and conservation – Buy David Shiffman a Less Ugly Pair of Sunglasses – ostensibly about replacing David’s legendarily hideous sunglasses with something a bit more aesthetic. Of course, anyone digging into the stretch goals quickly realized that this was less about sunglasses and more about funding some cool research and outreach projects we’re currently working on; projects like a hammerhead conservation genetics analysis, building a marine ecology drone, and sending students from underserved schools of a shark tagging trip. This was made more explicit when we hit our first goal in the first 36 hours of funding.

Last week, we launched a novel little experiment in crowdfunding marine science and conservation – Buy David Shiffman a Less Ugly Pair of Sunglasses – ostensibly about replacing David’s legendarily hideous sunglasses with something a bit more aesthetic. Of course, anyone digging into the stretch goals quickly realized that this was less about sunglasses and more about funding some cool research and outreach projects we’re currently working on; projects like a hammerhead conservation genetics analysis, building a marine ecology drone, and sending students from underserved schools of a shark tagging trip. This was made more explicit when we hit our first goal in the first 36 hours of funding.

With the first funding goal achieved, I decided we needed a cool perk, something not particularly expensive to produce but completely novel and cool enough to justify making a heftier donation. And, of course, it needed to be thematically related to the spirit of the project.

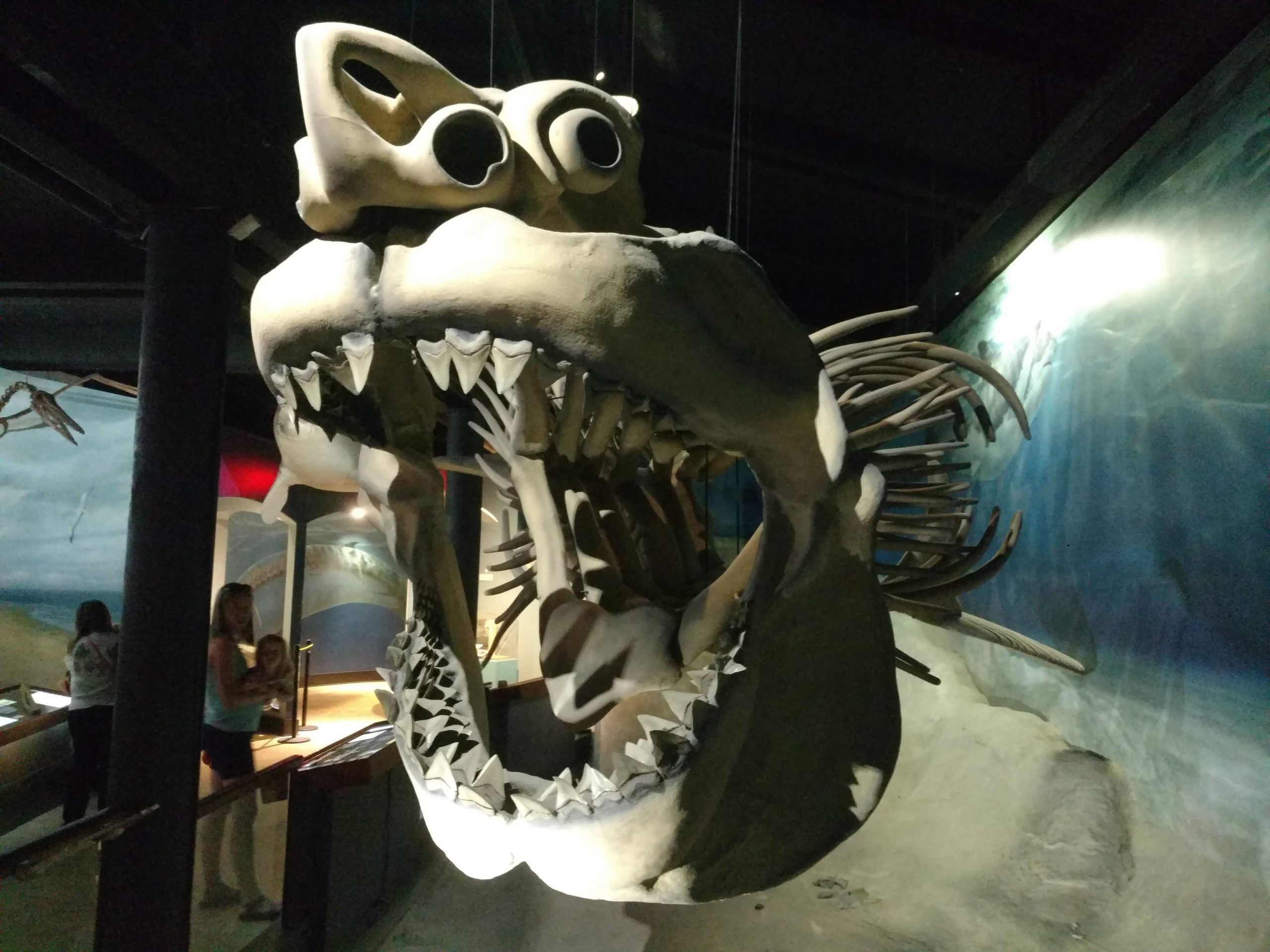

Enter the Megalodon.

I have a Megalodon tooth, a 10 million year old fossil that I found at the Aurora phosphate mine back when PCS Phosphate allowed fossil hunters into their mine. At 4 inches crown-to-tip, it’s not the biggest Meg Tooth on record, but it is a hefty, near perfect specimen. As it happens, I also have a 3D printer, a Printrbot Simple Metal, which, though small and basic, is an absolute tank (I personally hate the lasercut wood look of a lot of consumer-level 3D printers). So I thought, why not scan my Megalodon tooth and offer a 3D-printed replica as a perk for major funders.

Of course, I had never mad a 3D scan before.

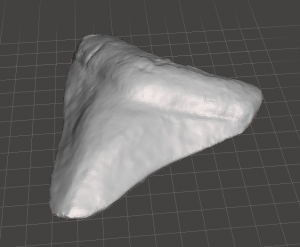

I like to dive into things head first, so I announced the 3D printed Megalodon tooth perk and then went to work figuring out how to scan this thing. Five hours later, the first tooth rolled of the printer, a perfect replica.

If the fact that I have a 3D printer and am building ecodrones hasn’t given it away, I’m a bit of a technocrat. Technically speaking, I’m a practical technocrat–I actually don’t think technology is ever really the best solution to large societal problems, but rather that we, as a society, are so resistant to personal, cultural, and behavioral changes, that technologies often ends up providing the only practical solutions to global issues. I’m rarely surprised by new tech, but the process of duplicating a unique object, and doing so in barely 5 hours with no background or past experience in the process, blew my mind.

It began with this excellent Instructable by Gian Pablo Villamil: Making a 3D print of a real object using 123D Catch and Meshmixer. Both 123D Catch and Meshmixer are free programs (for non-commercial use). 123D Catch works with you smartphone. By taking 30+ pictures of an object from different angles (and with a background that makes it easy for the program to orient photographs) 123D Catch can generate a 3D model of any object. A bit of cleanup in its desktop software and you’re ready to export a shape file. Meshmixer then allows you to tweek that shape file, correct errors, and add features that will make it 3D printable (in this case, the bottom of the tooth is flat, which produces a beautiful print).

Then it’s just a matter of taking your shape file over to your prefered 3D printing package, adjusting the print settings, and slicing the file.

The end result was awesome.

And yes, some of those teeth are printed in wood filament. Because that is a thing now, too.

For all that we, especially here at Southern Fried Science, focus on web and content-based outreach, there are few more powerful communication tools than physical things. We can write reams on the glory, power, and extinct-ness of the Megalodon, but none of that is nearly as effective as putting the tooth of the ocean’s biggest shark into someone’s hand.

And it doesn’t stop with Megalodon teeth (of which mine will be available through Youmagine after our crowdfunding campaign has ended). Already you can print out an entire Hammerhead Skull. Octopuses appear to be the overwhelming favorites of the 3D printing community. And Mieke Roth is crowdfunding 3D printed anatomic models. Imagine 10 years ago being able to duplicate a 3-dimensional object, using relatively cheap consumer equipment (none of my gear is particularly fancy: my computer is a basic HP laptop that can’t even run newer video games, the Printrbot is one of the most affordable 3D printers, and my Android phone is a couple generations old). For all our jokes about flying cars and hover boards, the future is pretty awesome. Technology is exciting. Technology is fun. And hardware can serve as much as a platform for physical outreach as WordPress and Twitter have for online outreach. And it’s not just that the technology is there, it’s that the technology is easy.

3D printing lets us take our digital outreach efforts and make them physical.